“Inside the Pulse: How Hobby-Grade Servo Motors Work”

- DAS PILOT

- Jun 5, 2025

- 2 min read

Whether you're building a remote-controlled car, a robotic arm, or a model airplane, servo motors are the silent workhorses behind precise motion. But have you ever wondered what makes these compact devices tick? Let’s open one up—figuratively—and break down how hobby-grade servos work.

🛠 The Building Blocks of a Servo Motor

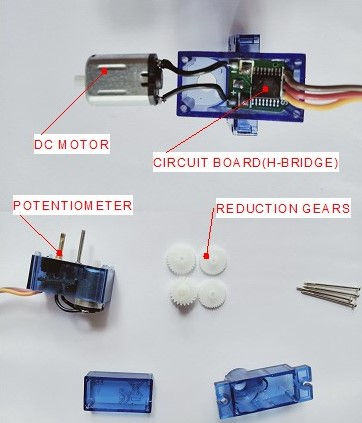

A typical hobby-grade servo consists of four main components:

A high-speed, low-torque DC motor

A reduction gearbox

A potentiometer (position sensor)

An H-bridge control circuit

Each part plays a crucial role in translating electrical pulses into precise physical movement.

⚙️ Gear Down to Power Up

At the heart of the servo is a small DC motor. On its own, it spins fast but lacks the torque needed to move heavier loads. That’s where the reduction gearbox comes in. By reducing the motor's RPM (revolutions per minute), the gearbox increases output torque, making the servo strong enough to move robot joints, control flaps on model planes, or steer RC cars.

🌀 Feedback via Potentiometer

Connected to the output shaft is a potentiometer, a variable resistor that changes its output voltage based on rotation angle. As the shaft turns, so does the potentiometer, continuously sending a voltage signal that reflects the shaft's current position.

🔁 Precision with Feedback Control

The servo receives an input signal—typically a pulse-width modulated (PWM) signal—that tells it the desired position. The control circuit compares this input with the feedback from the potentiometer.

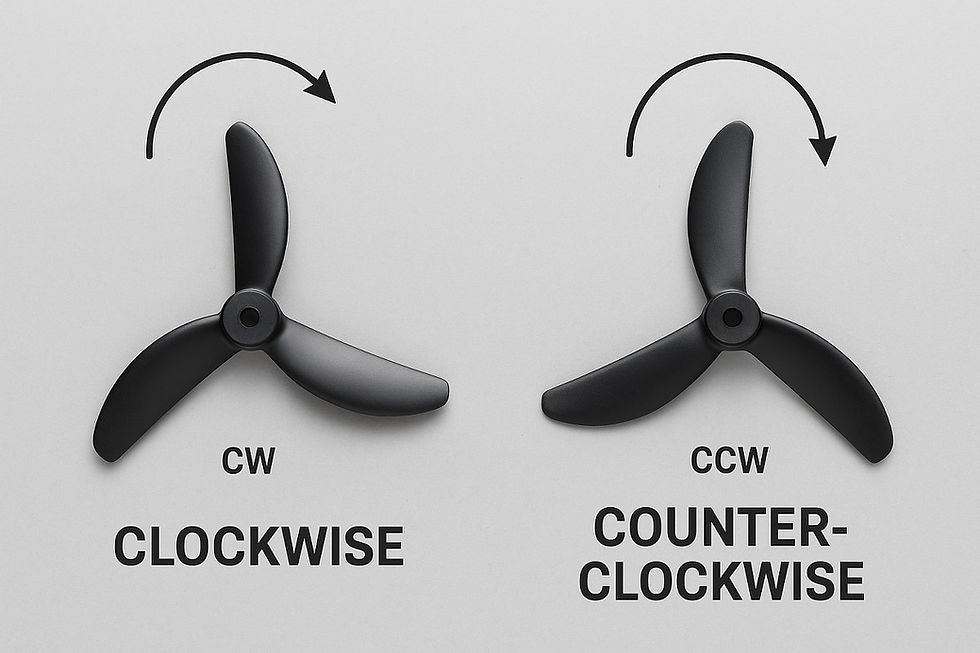

When there’s a difference between the current position and the target position, the H-bridge circuit kicks in. It adjusts the polarity of voltage applied to the motor, allowing it to rotate clockwise or counter-clockwise until the difference is zero. This feedback loop ensures the servo reaches and holds the correct angle.

🔄 Limited but Precise Rotation

Most hobby-grade servos are limited to about 180 degrees of rotation, governed by the mechanical limits of the potentiometer and internal stops. This restricted range may seem like a downside, but it’s perfect for many applications that demand repeatable and controlled movement.

🔧 Final Thoughts

Servo motors pack a surprising amount of engineering into a small package. Their combination of feedback control, gearing, and bidirectional movement makes them a staple in DIY electronics, robotics, and beyond. Next time you see a servo buzz to life, you’ll know the elegant process that’s turning pulses into motion.

Comments